Discountable price Abrasive Sandblasting - Cast Stainless Steel Shot – Feng Erda

Discountable price Abrasive Sandblasting - Cast Stainless Steel Shot – Feng Erda Detail:

Model/Size:0.03—3.00mm

Product Detail:

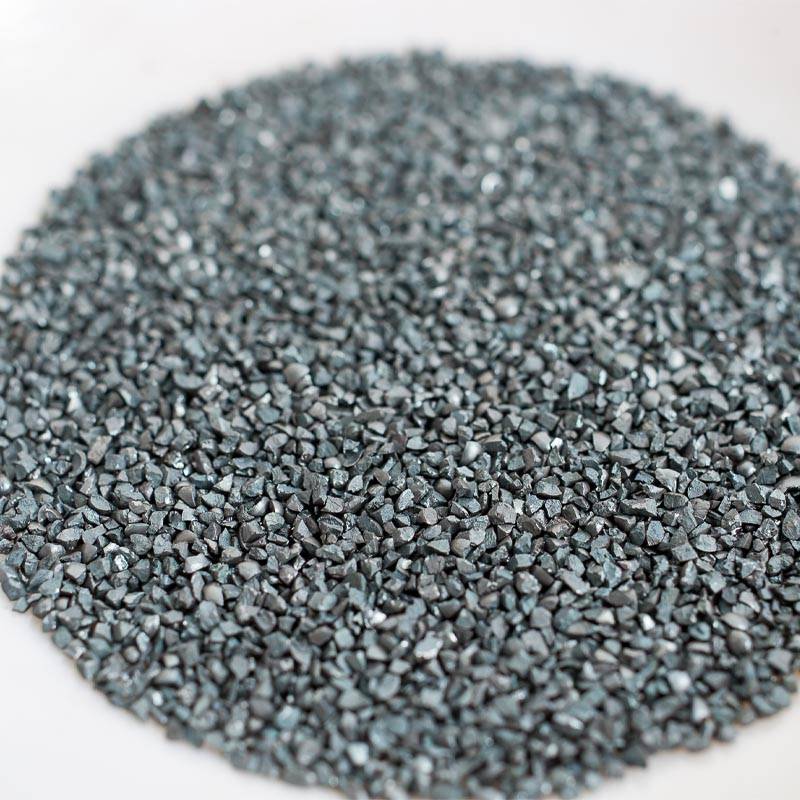

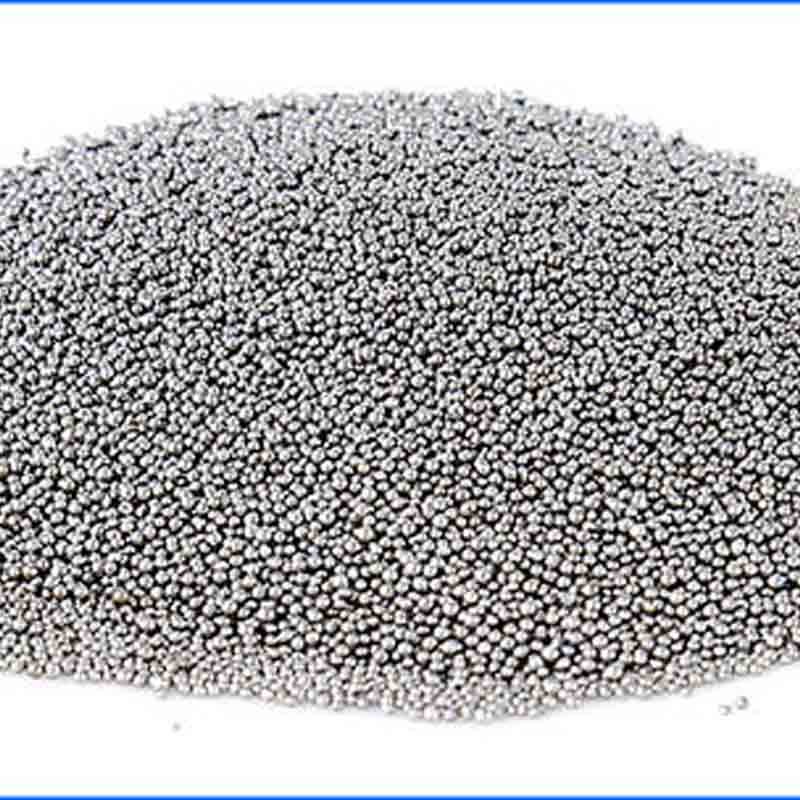

Stainless steel shot is the media type that have become more popular. This products perform similarly to steel shot, however, is made of stainless steel. It contain a higher concentration of nickel and chromium. And is good medias to consider when ferrous contamination of the work piece cannot be tolerated. This products is cast products and is occasionally referred to as Cast Stainless Steel Shot .

Using Cast Stainless Steel Shot on smooth and textured pavers brings out the stones unique appearance, and the possibility of developing unsightly rust spots on the surface of blasted concrete and granite stones due to the remains of ferritic particles is ruled out.

Key Specifications:

|

ltem |

Specification |

||||

|

|

|

||||

|

TeXture of material |

SUS304 |

SUS430 |

SUS410 |

SUS201 |

|

|

Chemical compostion |

C |

<0.15% |

<0.15% |

<0.15% |

<0.15% |

|

|

Cr |

16-18% |

16-18% |

11-13% |

14-16% |

|

|

Ni |

6-10% |

/ |

/ |

1-2% |

|

|

Mn |

<2.00% |

1.00% |

1.00% |

<2.00% |

|

|

Si |

<1.0% |

|||

|

|

S |

≤0.03% |

|||

|

|

P |

≤0.03% |

|||

|

Density |

7.8g/cm³ |

||||

|

Hardness |

400-600HV |

||||

|

Ervin life |

6500 times |

||||

|

Model |

Size mm |

3.5 |

3.0 |

2.5 |

2.00 |

1.70 |

1.40 |

1.25 |

1.00 |

0.8 |

0.7 |

0.6 |

0.5 |

0.4 |

0.3 |

0.2 |

0.14 |

0.09 |

<0.09 |

|

S10 |

0.2-0.05 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5% |

|

|

|

|

S20 |

0.3-0.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

5% |

|

|

90% |

|

|

S30 |

0.5-0.14 |

|

|

|

|

|

|

|

|

|

|

|

5% |

|

|

|

90% |

|

|

|

S40 |

0.8-0.4 |

|

|

|

|

|

|

|

|

5% |

|

|

|

90% |

|

|

|

|

|

|

S50 |

1.0-0.6 |

|

|

|

|

|

|

|

5% |

|

|

90% |

|

|

|

|

|

|

|

|

S60 |

1.25-0.7 |

|

|

|

|

|

|

5% |

|

|

90% |

|

|

|

|

|

|

|

|

|

S100 |

1.4-1.0 |

|

|

|

|

|

5% |

|

90% |

|

|

|

|

|

|

|

|

|

|

|

S150 |

1.7-1.25 |

|

|

|

|

5% |

|

90% |

|

|

|

|

|

|

|

|

|

|

|

|

S200 |

2.0-1.4 |

|

|

|

5% |

|

90% |

|

|

|

|

|

|

|

|

|

|

|

|

|

S300 |

3.0-1.7 |

|

5% |

|

|

90% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Size mm |

|

3.5 |

3.0 |

2.5 |

2.0 |

1.7 |

1.4 |

1.25 |

1.0 |

0.8 |

0.7 |

0.6 |

0.5 |

0.4 |

0.3 |

0.2 |

0.14 |

0.09 |

<0.09 |

Main fields of application:

Blast cleaning, deburring, surface finishing, surface-improvement

All types of aluminium castings and forgings

Zinc pressure die castings

Non-ferrous metals and special alloys

Stainless steel castings and forgings

Machinery and welded structures in stainless steel

Concrete and natural stones

Advantages:

Great durability

Short blasting times

Bright appearance

Rust-free surfaces

Reduced wear of blast cleaning equipment

Low waste disposal costs

Dust-free blasting process

Can be recycled many times

Before cleaning

After cleaning

Product detail pictures:

Related Product Guide:

We have now sophisticated machines. Our solutions are exported to the USA, the UK and so on, enjoying a great reputation amid consumers for Discountable price Abrasive Sandblasting - Cast Stainless Steel Shot – Feng Erda , The product will supply to all over the world, such as: Kuala Lumpur, Serbia, Denver, Our factory covers an area of 12,000 square meters, and has a staff of 200 people, among which there are 5 technical executives. We are specialized in producing.We have rich experience in export. Welcome to contact us and your enquiry will be replied as soon as possible.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.