factory Outlets for Shot Blasted Stainless Steel - Grinding Steel Shot – Feng Erda

factory Outlets for Shot Blasted Stainless Steel - Grinding Steel Shot – Feng Erda Detail:

Model/Size:0.4-2.5mm

Product Detail:

Alloy grinding steel shot is based on the high-carbon steel shot,low-carbon steel shot,and low vanadium steel shot,considering the fatal weakness of the above products:air hole,cracks,hardness difference,develop the new products by reaserch the forging technology,it can choose the different material according to the different usage,its cost depends on the application area,can long the usage life,its has high cost performance.steel cut wire shots are available in three different hardness: 45-50 HRC, 50-55 HRC and 55-60 HRC with size ranging from 0.20mm to 2.50mm. Our cut wire shots conform to SAE J441, AMS 2431 and VDFI 8001.

Key Specifications:

| SIZE: | 0.2-2.5MM |

| HARDNESS: | HRC40-50

HRC45-55 HRC50-60 HRC>60 |

| SHAPE | G1 Conditioned

G2 Double Conditioned G3 Spherical |

|

PROJECT |

SPECIFICATION |

TEST METHOD |

|||

|

CHEMICAL COMPOSITION |

C |

0.45-0.75% |

P |

<0.04% |

ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

|

|

Si |

0.10-0.30% |

Cr |

/ |

|

|

|

Mn |

0.40-1.5% |

Mo |

/ |

|

|

|

S |

<0.04% |

Ni |

/ |

|

|

MICROTRUCTURE |

Martensite or troosite or deformed pearlite |

GB/T 19816.5-2005 |

|||

|

Density |

≥7.40g/cm³ |

GB/T 19816.4-2005 |

|||

|

EXTERNALFORM |

Homogeneous size,perfect glossiness,ball shape |

Visual |

|||

Why choose Alloy Grinding Shot?

Grinding shot cross section

Steel shot cross section

Grinding Shot Raw Materials

Steel Shot Raw Materials

①,It is made of forged steel wire,no air hole,cracks,and hardness difference.

②,According to the different requirements of different fields, we can choose different materials of steel wire.

③,The Grinding shot is more resilience, and the life is 1.5 times that of steel shot.

④,The workpiece cleaned by Grinding shot is silver-white, and the surface cleaned by Cast steel shot turns dark gray.

⑤,The cleaning effect is more thorough than that of cast steel shot, and there is no need for secondary cleaning. After cleaning, the roughness of workpiece meets the requirements.

⑥,Due to the advantages of no air hole, no cracks, and not easy to be broken in abrasive forging grinding steel shot, the filling amount in blasting process is less, the dust in blasting process is less, the working labor intensity is low, and the environmental pollution can be reduced.

Comparison of Advantages

|

|

Low carbon steel shot |

Grinding steel shot |

High carbon steel shot |

|

C |

0.08-0.20 |

0.45-0.75 |

0.80-1.20 |

|

S |

≤0.05 |

<0.03 |

≤0.05 |

|

Mn |

0.35-1.50 |

0.50-1.50 |

0.50-1.20 |

|

P |

≤0.05 |

<0.03 |

≤0.05 |

|

Si |

0.10-2.00 |

0.30-0.60 |

≥0.40 |

|

HRC |

40-50 |

40-60/50-60 |

40-50 |

|

Salinity |

≤45mg/㎡ |

≤18mg/㎡ |

≤45mg/㎡ |

|

fatigue life |

4000-4200 |

5400-5800 |

2500-2800 |

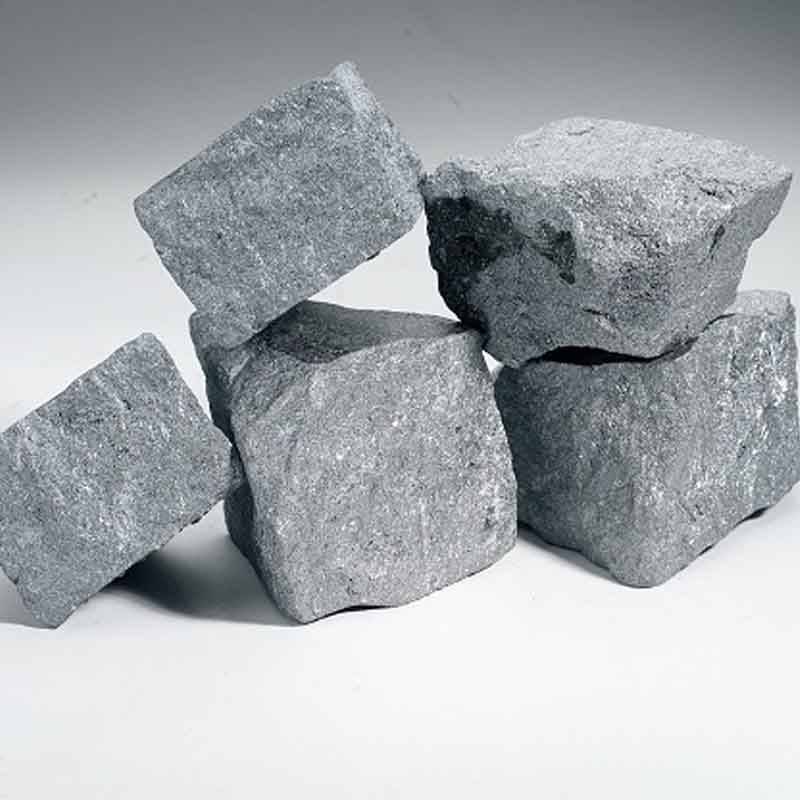

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for factory Outlets for Shot Blasted Stainless Steel - Grinding Steel Shot – Feng Erda , The product will supply to all over the world, such as: Czech Republic, Peru, Bolivia, Selling our products causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.