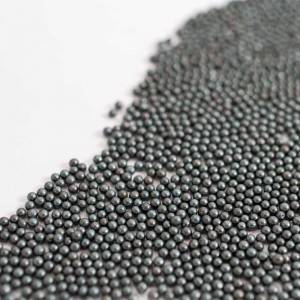

Factory Supply China Stainless Steel Shot for Shot Blasting Equipment

We have many excellent staff members good at marketing, QC, and dealing with kinds of troublesome problem in the production process for Factory Supply China Stainless Steel Shot for Shot Blasting Equipment, Welcome worldwide prospects to get in touch with us for company and long-term cooperation. We’ll be your reliable partner and supplier.

We have many excellent staff members good at marketing, QC, and dealing with kinds of troublesome problem in the production process for China Stainless Steel Shot, Stainless steel cut wire, We’ve been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we have the whole capacity to supply you happy solutions.

Model/Size:S110-S930/Φ0.3mm-2.8mm

Product Detail:

High carbon steel shot, made out of special steel,hardened and tempered, have a content in carbon greater than 0.85%.through atomization process,spherical particles made of molten steel.Fengerda strictly controls every link of production, especially the control of deoxidation and decarbonization, temperature in quenching process, as well as the elimination of pores and abnormity after forming, which improves the product to a new level.

Key Specifications:

|

PROJECT |

SPECIFICATION |

TEST METHOD |

|||

|

CHEMICAL COMPOSITION |

|

0.8-1.2% |

P |

≤0.05% |

ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

|

Si |

≥0.4% |

Cr |

/ |

||

|

Mn |

0.35-1.2% |

Mo |

/ |

||

|

S |

≤0.05% |

Ni |

/ |

||

|

MICROTRUCTURE |

Homogeneous Martensite or Bainite |

GB/T 19816.5-2005 |

|||

|

Density |

≥7.0*10³kg/m³(7.0kg/dm³) |

GB/T 19816.4-2005 |

|||

|

EXTERNALFORM |

Air hole < 10%. Conjoins. Sharp corner. Deformity Rate< 10% |

Visual |

|||

|

HARDNESS |

HV:390-530(HRC39.8-51.1) |

GB/T 19816.3-2005 |

|||

Processing Steps:

Advantages:

High Carbon Rounded Steel Shot using the traditional manufacturing technique,used for blast cleaning and shot peening mainly.Perfectly controlled heat treatments provide it with optimum resilience and resistance to fatigue.

and finish metal parts that require increased wear and fatigue properties. In the process, shot bombards the metal part, creating small dimples in the surface.

The dimples cause compression stresses in the surface of the part, increasing the metal’s resistance to cracks, fatigue, and corrosion. Shot peening is used for critical, high-wear components such as gears, shafts and metallic skins for advanced aerodynamic products.

Applications:

Our high carbon steel shot is used in various applications like; desanding, descaling, cleaning, shot peening etc.. The centrifugal atomization process and double heat treatment at the Airblast plants, as well as continues quality control measures, ensures the shot to be of the highest quality.

Surface blast cleaning of forgings, heattreated pieces, steel pipes, sections and steel structures, surface treatment before painting, shot peening of work pieces.

Surface blast cleaning of stainless steel plates, thin steel plates, non ferrous alloys, dacromet coat.

We have many excellent staff members good at marketing, QC, and dealing with kinds of troublesome problem in the production process for Factory Supply China Stainless Steel Shot for Shot Blasting Equipment, Welcome worldwide prospects to get in touch with us for company and long-term cooperation. We’ll be your reliable partner and supplier.

Factory Supply China Stainless Steel Shot, Stainless Steel Cut Wire, We’ve been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we have the whole capacity to supply you happy solutions.