Leading Manufacturer for FeSi72 - FerroManganese – Feng Erda

Leading Manufacturer for FeSi72 - FerroManganese – Feng Erda Detail:

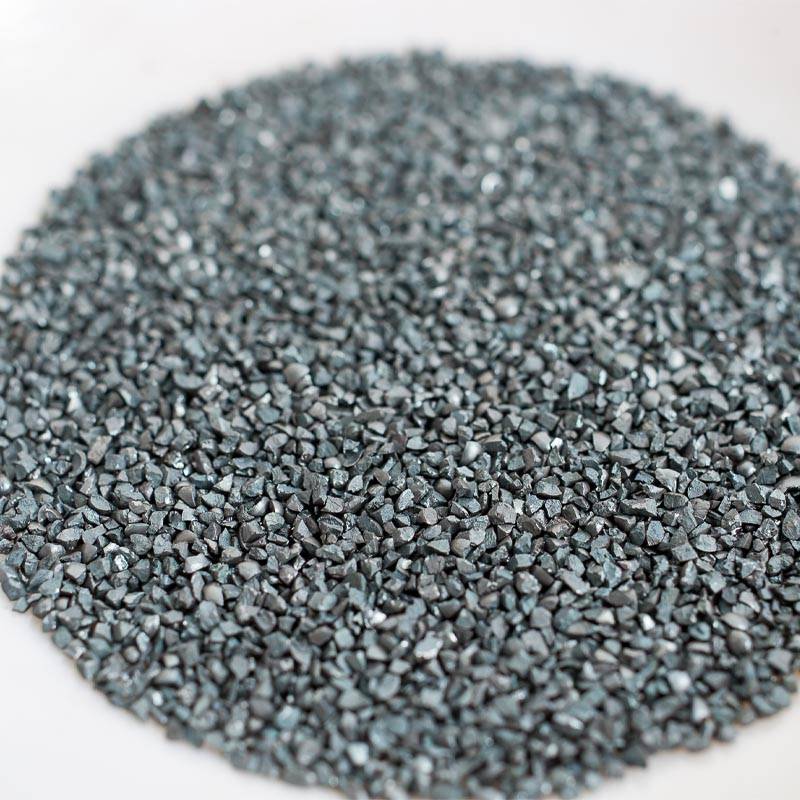

Size:1-100mm

Basic Info:

| Ferromanganese International Brand | ||||||||

|

category |

Brand name |

chemical composition(wt%) |

||||||

|

Mn |

C |

Si |

P |

S |

||||

|

Ⅰ |

Ⅱ |

Ⅰ |

Ⅱ |

|||||

|

Range |

≤ |

|||||||

|

Low carbon ferromanganese |

FeMn82C0.2 |

85.0—92.0 |

0.2 |

1.0 |

2.0 |

0.10 |

0.30 |

0.02 |

|

FeMn84C0.4 |

80.0—87.0 |

0.4 |

1.0 |

2.0 |

0.15 |

0.30 |

0.02 |

|

|

FeMn84C0.7 |

80.0—87.0 |

0.7 |

1.0 |

2.0 |

0.20 |

0.30 |

0.02 |

|

|

category |

Brand name |

chemical composition(wt%) |

||||||

|

Mn |

C |

Si |

P |

S |

||||

|

Ⅰ |

Ⅱ |

Ⅰ |

Ⅱ |

|||||

|

Range |

≤ |

|||||||

|

Medium carbon ferromanganese |

FeMn82C1.0 |

78.0—85.0 |

1.0 |

1.5 |

2.0 |

0.20 |

0.35 |

0.03 |

|

FeMn82C1.5 |

78.0—85.0 |

1.5 |

1.5 |

2.0 |

0.20 |

0.35 |

0.03 |

|

|

FeMn78C2.0 |

75.0—82.0 |

2.0 |

1.5 |

2.5 |

0.20 |

0.40 |

0.03 |

|

|

category |

Brand name |

chemical composition(wt%) |

||||||

|

Mn |

C |

Si |

P |

S |

||||

|

Ⅰ |

Ⅱ |

Ⅰ |

Ⅱ |

|||||

|

Range |

≤ |

|||||||

|

High carbon ferromanganese |

FeMn78C8.0 |

75.0—82.0 |

8.0 |

1.5 |

2.5 |

0.20 |

0.33 |

0.03 |

|

FeMn74C7.5 |

70.0—77.0 |

7.5 |

2.0 |

3.0 |

0.25 |

0.38 |

0.03 |

|

|

FeMn68C7.0 |

65.0—72.0 |

7.0 |

2.5 |

4.5 |

0.25 |

0.40 |

0.03 |

|

Ferromanganese is a kind of ferroalloy that is composed of iron and manganese.is made by heating a mixture of the oxides MnO2 and Fe2O3, with carbon, usually as coal and coke, in either a blast furnace or an electric arc furnace-type system, called a submerged arc furnace. The oxides undergo carbothermal reduction in the furnaces, producing the ferromanganese.

It can be divided into High carbon ferromanganese/HCFeMn(C:7.0%-8.0%),Medium carbon ferromanganese/MCFeMn:(C:1.0-2.0%),and Low carbon ferromanganese/LCFeMn(C<0.7%). it is available in a wide range of sizes .

Ferromanganese production takes manganese ore as raw material and lime as auxiliary material,uses electric furnace to smelt.

Application:

①Ferromanganese performs well in steel-making,it is deoxidizer and alloying constituent,and meanwhile can reduce sulfur content and damage caused by sulfur.

②Liquid ateel mixed by ferromanganese can improve mechanical properties od steel with high strength,toughness,wear resistance,ductility,ect.

③Ferromanganese is a very important auxiliary material in steel-making and iron casting industries.

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for Leading Manufacturer for FeSi72 - FerroManganese – Feng Erda , The product will supply to all over the world, such as: UAE, Cologne, Victoria, We strive for excellence, constant improvement and innovation, is committed to make us the "customer trust" and the "first choice of engineering machinery accessories brand" suppliers. Choose us, sharing a win-win situation!

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.