Manufactur standard Gautam Ferro Alloys - FerroSilicon – Feng Erda

Manufactur standard Gautam Ferro Alloys - FerroSilicon – Feng Erda Detail:

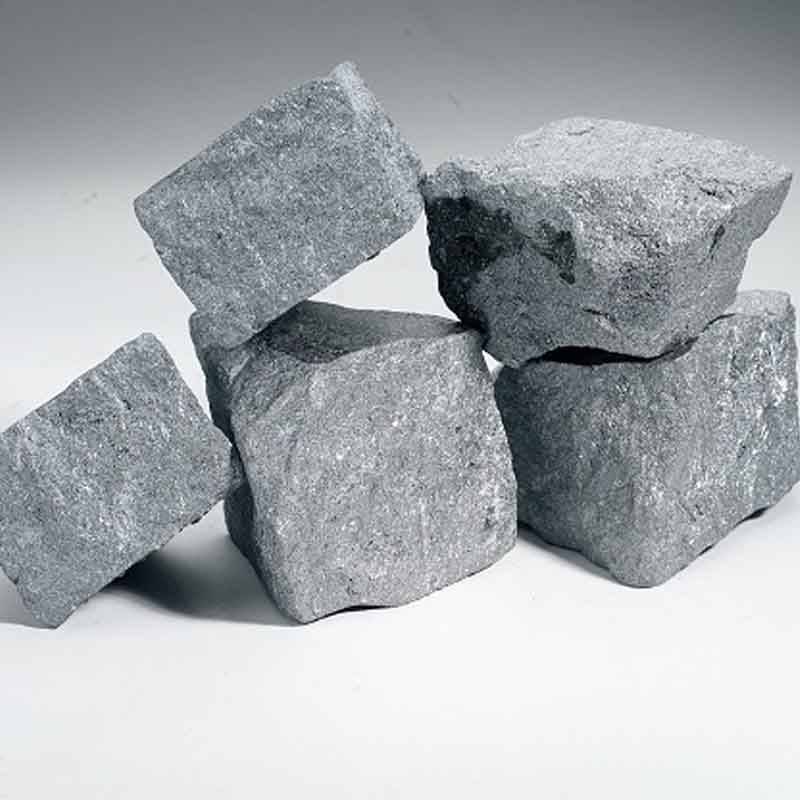

Size:1-100mm

Basic Info:

| Ferrosilicon International Brand(GB2272-2009) | ||||||||

|

Brand name |

chemical composition |

|||||||

|

Si |

Al |

Ca |

Mn |

Cr |

P |

S |

C |

|

|

Range |

≤ |

|||||||

|

FeSi90Al1.5 |

87.0—95.0 |

1.5 |

1.5 |

0.4 |

0.2 |

0.04 |

0.02 |

0.2 |

|

FeSi90Al3.0 |

87.0—95.0 |

3.0 |

1.5 |

0.4 |

0.2 |

0.04 |

0.02 |

0.2 |

|

FeSi75Al0.5-A |

74.0—80.0 |

0.5 |

1.0 |

0.4 |

0.5 |

0.035 |

0.02 |

0.1 |

|

FeSi75Al0.5-B |

72.0—80.0 |

0.5 |

1.0 |

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi75Al1.0-A |

74.0—80.0 |

1.0 |

1.0 |

0.4 |

0.3 |

0.035 |

0.02 |

0.1 |

|

FeSi75Al1.0-B |

72.0—80.0 |

1.0 |

1.0 |

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi75Al1.5-A |

74.0—80.0 |

1.5 |

1.0 |

0.4 |

0.3 |

0.035 |

0.02 |

0.1 |

|

FeSi75Al1.5-B |

72.0—80.0 |

1.5 |

1.0 |

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi75Al2.0-A |

74.0—80.0 |

2.0 |

1.0 |

0.4 |

0.3 |

0.035 |

0.02 |

0.1 |

|

FeSi75Al2.0-B |

72.0—80.0 |

2.0 |

— |

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi75-A |

74.0—80.0 |

— |

— |

0.4 |

0.3 |

0.035 |

0.02 |

0.1 |

|

FeSi75-B |

72.0—80.0 |

— |

— |

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi65 |

65.0—72.0 |

— |

— |

0.6 |

0.5 |

0.04 |

0.02 |

— |

|

FeSi45 |

40.0—47.0 |

— |

— |

0.7 |

0.5 |

0.04 |

0.02 |

— |

Ferrosilicon is a kind of ferroalloy that is composed produced by reduction of silica or sand with coke in the presence of iron. Typical sources of iron are scrap iron or millscale. Ferrosilicons with silicon content up to about 15% are made in blast furnaces lined with acid fire bricks. Ferrosilicons with higher silicon content are made in electric arc furnaces. The usual formulations on the market are ferrosilicons with 60-75%silicon. The remainder is iron, with about 2% consisting of other elements like aluminium and calcium. An overabundance of silica is used to prevent formation of silicon carbide.

Application:

①As deoxidizer and alloy agent in steelmaking industry

②As inoculant and spheroidizing agent in cast iron

③As reducing agent in ferroalloy production

④As displacing agent in the smelting of magnesium

⑤In other applocation fields,milled or atomizing silicon iron powder can be used as suspended phase.

Product detail pictures:

Related Product Guide:

As a way to ideal meet up with client's desires, all of our operations are strictly performed in line with our motto "High Top quality, Competitive Cost, Fast Service" for Manufactur standard Gautam Ferro Alloys - FerroSilicon – Feng Erda , The product will supply to all over the world, such as: Istanbul, venezuela, European, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!