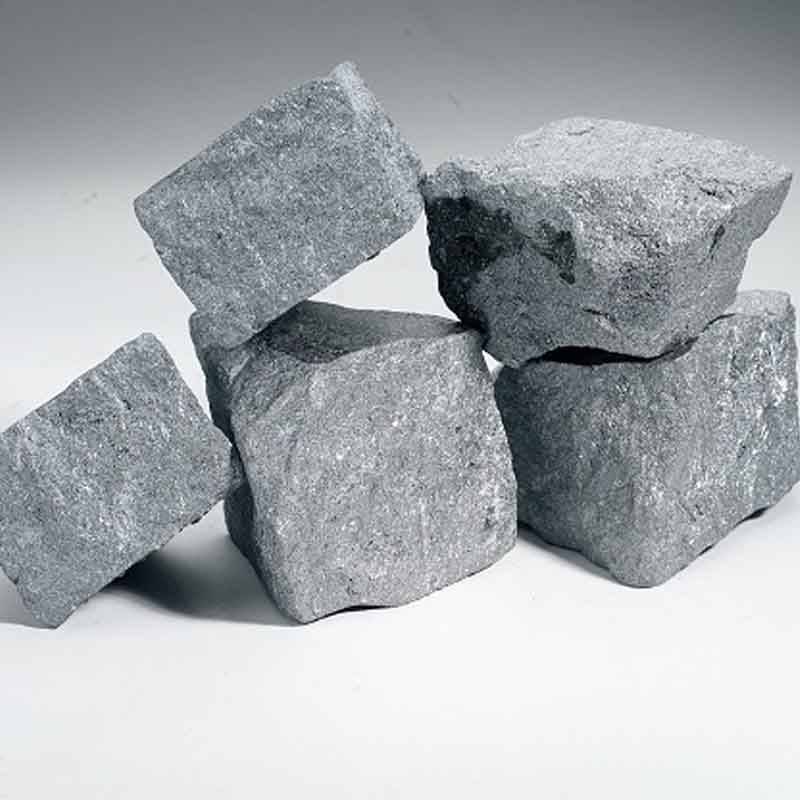

Quality Inspection for - FerroSilicon – Feng Erda

Quality Inspection for - FerroSilicon – Feng Erda Detail:

Size:1-100mm

Basic Info:

| Ferrosilicon International Brand(GB2272-2009) | ||||||||

|

Brand name |

chemical composition |

|||||||

|

Si |

Al |

Ca |

Mn |

Cr |

P |

S |

C |

|

|

Range |

≤ |

|||||||

|

FeSi90Al1.5 |

87.0—95.0 |

1.5 |

1.5 |

0.4 |

0.2 |

0.04 |

0.02 |

0.2 |

|

FeSi90Al3.0 |

87.0—95.0 |

3.0 |

1.5 |

0.4 |

0.2 |

0.04 |

0.02 |

0.2 |

|

FeSi75Al0.5-A |

74.0—80.0 |

0.5 |

1.0 |

0.4 |

0.5 |

0.035 |

0.02 |

0.1 |

|

FeSi75Al0.5-B |

72.0—80.0 |

0.5 |

1.0 |

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi75Al1.0-A |

74.0—80.0 |

1.0 |

1.0 |

0.4 |

0.3 |

0.035 |

0.02 |

0.1 |

|

FeSi75Al1.0-B |

72.0—80.0 |

1.0 |

1.0 |

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi75Al1.5-A |

74.0—80.0 |

1.5 |

1.0 |

0.4 |

0.3 |

0.035 |

0.02 |

0.1 |

|

FeSi75Al1.5-B |

72.0—80.0 |

1.5 |

1.0 |

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi75Al2.0-A |

74.0—80.0 |

2.0 |

1.0 |

0.4 |

0.3 |

0.035 |

0.02 |

0.1 |

|

FeSi75Al2.0-B |

72.0—80.0 |

2.0 |

— |

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi75-A |

74.0—80.0 |

— |

— |

0.4 |

0.3 |

0.035 |

0.02 |

0.1 |

|

FeSi75-B |

72.0—80.0 |

— |

— |

0.5 |

0.5 |

0.04 |

0.02 |

0.2 |

|

FeSi65 |

65.0—72.0 |

— |

— |

0.6 |

0.5 |

0.04 |

0.02 |

— |

|

FeSi45 |

40.0—47.0 |

— |

— |

0.7 |

0.5 |

0.04 |

0.02 |

— |

Ferrosilicon is a kind of ferroalloy that is composed produced by reduction of silica or sand with coke in the presence of iron. Typical sources of iron are scrap iron or millscale. Ferrosilicons with silicon content up to about 15% are made in blast furnaces lined with acid fire bricks. Ferrosilicons with higher silicon content are made in electric arc furnaces. The usual formulations on the market are ferrosilicons with 60-75%silicon. The remainder is iron, with about 2% consisting of other elements like aluminium and calcium. An overabundance of silica is used to prevent formation of silicon carbide.

Application:

①As deoxidizer and alloy agent in steelmaking industry

②As inoculant and spheroidizing agent in cast iron

③As reducing agent in ferroalloy production

④As displacing agent in the smelting of magnesium

⑤In other applocation fields,milled or atomizing silicon iron powder can be used as suspended phase.

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer you excellent services to each individual client, but also are ready to receive any suggestion offered by our buyers for Quality Inspection for - FerroSilicon – Feng Erda , The product will supply to all over the world, such as: Belgium, Madagascar, Turkey, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, please feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our products, please feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.