Super Purchasing for Abrasive Blasting - Cast Stainless Steel Shot – Feng Erda

Super Purchasing for Abrasive Blasting - Cast Stainless Steel Shot – Feng Erda Detail:

Model/Size:0.03—3.00mm

Product Detail:

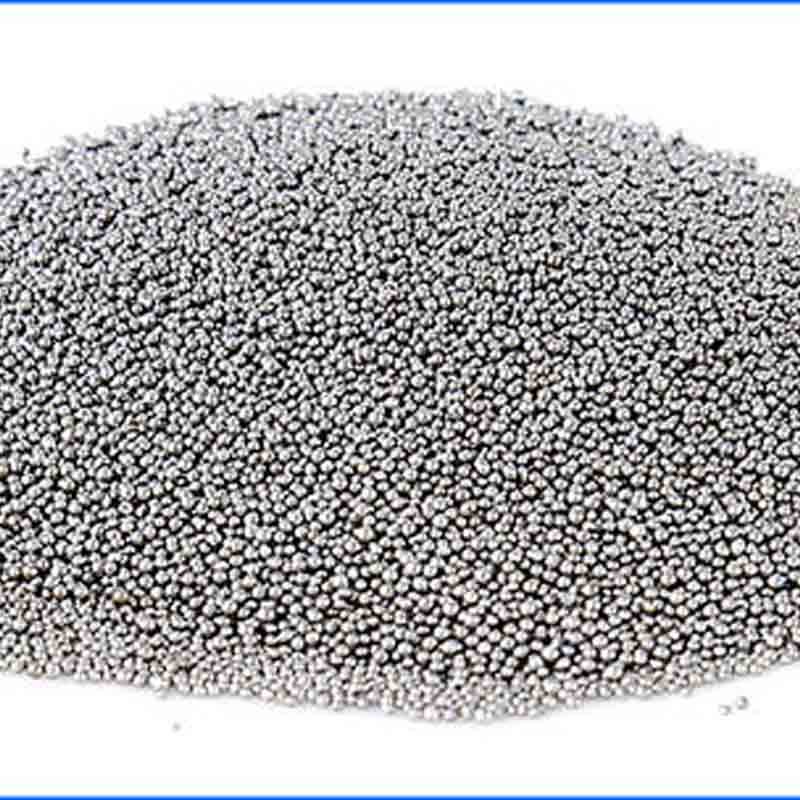

Stainless steel shot is the media type that have become more popular. This products perform similarly to steel shot, however, is made of stainless steel. It contain a higher concentration of nickel and chromium. And is good medias to consider when ferrous contamination of the work piece cannot be tolerated. This products is cast products and is occasionally referred to as Cast Stainless Steel Shot .

Using Cast Stainless Steel Shot on smooth and textured pavers brings out the stones unique appearance, and the possibility of developing unsightly rust spots on the surface of blasted concrete and granite stones due to the remains of ferritic particles is ruled out.

Key Specifications:

|

ltem |

Specification |

||||

|

|

|

||||

|

TeXture of material |

SUS304 |

SUS430 |

SUS410 |

SUS201 |

|

|

Chemical compostion |

C |

<0.15% |

<0.15% |

<0.15% |

<0.15% |

|

|

Cr |

16-18% |

16-18% |

11-13% |

14-16% |

|

|

Ni |

6-10% |

/ |

/ |

1-2% |

|

|

Mn |

<2.00% |

1.00% |

1.00% |

<2.00% |

|

|

Si |

<1.0% |

|||

|

|

S |

≤0.03% |

|||

|

|

P |

≤0.03% |

|||

|

Density |

7.8g/cm³ |

||||

|

Hardness |

400-600HV |

||||

|

Ervin life |

6500 times |

||||

|

Model |

Size mm |

3.5 |

3.0 |

2.5 |

2.00 |

1.70 |

1.40 |

1.25 |

1.00 |

0.8 |

0.7 |

0.6 |

0.5 |

0.4 |

0.3 |

0.2 |

0.14 |

0.09 |

<0.09 |

|

S10 |

0.2-0.05 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5% |

|

|

|

|

S20 |

0.3-0.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

5% |

|

|

90% |

|

|

S30 |

0.5-0.14 |

|

|

|

|

|

|

|

|

|

|

|

5% |

|

|

|

90% |

|

|

|

S40 |

0.8-0.4 |

|

|

|

|

|

|

|

|

5% |

|

|

|

90% |

|

|

|

|

|

|

S50 |

1.0-0.6 |

|

|

|

|

|

|

|

5% |

|

|

90% |

|

|

|

|

|

|

|

|

S60 |

1.25-0.7 |

|

|

|

|

|

|

5% |

|

|

90% |

|

|

|

|

|

|

|

|

|

S100 |

1.4-1.0 |

|

|

|

|

|

5% |

|

90% |

|

|

|

|

|

|

|

|

|

|

|

S150 |

1.7-1.25 |

|

|

|

|

5% |

|

90% |

|

|

|

|

|

|

|

|

|

|

|

|

S200 |

2.0-1.4 |

|

|

|

5% |

|

90% |

|

|

|

|

|

|

|

|

|

|

|

|

|

S300 |

3.0-1.7 |

|

5% |

|

|

90% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Size mm |

|

3.5 |

3.0 |

2.5 |

2.0 |

1.7 |

1.4 |

1.25 |

1.0 |

0.8 |

0.7 |

0.6 |

0.5 |

0.4 |

0.3 |

0.2 |

0.14 |

0.09 |

<0.09 |

Main fields of application:

Blast cleaning, deburring, surface finishing, surface-improvement

All types of aluminium castings and forgings

Zinc pressure die castings

Non-ferrous metals and special alloys

Stainless steel castings and forgings

Machinery and welded structures in stainless steel

Concrete and natural stones

Advantages:

Great durability

Short blasting times

Bright appearance

Rust-free surfaces

Reduced wear of blast cleaning equipment

Low waste disposal costs

Dust-free blasting process

Can be recycled many times

Before cleaning

After cleaning

Product detail pictures:

Related Product Guide:

We will constantly satisfy our respected customers with our good excellent, superior value and superior assistance due to we're additional experienced and far more hard-working and do it in cost-effective way for Super Purchasing for Abrasive Blasting - Cast Stainless Steel Shot – Feng Erda , The product will supply to all over the world, such as: Mauritania, Morocco, Washington, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products we offer, effective and satisfying consultation service is supplied by our specialist after-sale service group. Solution lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we are going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.