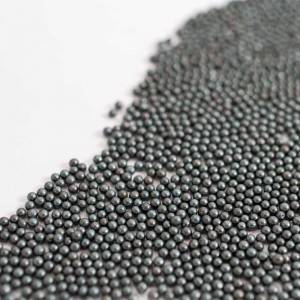

Top Suppliers China High Quality Stainless Steel Blast Media Cut Wire Shot SUS304 Cw0.8

With responsible good quality method, good status and excellent client services, the series of solutions produced by our company are exported to lots of countries and regions for Top Suppliers China High Quality Stainless Steel Blast Media Cut Wire Shot SUS304 Cw0.8, Our firm warmly welcome friends from everywhere in the globe to visit, examine and negotiate business enterprise.

With responsible good quality method, good status and excellent client services, the series of solutions produced by our company are exported to lots of countries and regions for China Steel Shot, Stainless Steel, Our solutions are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Model/Size:S110-S930/Φ0.3mm-2.8mm

Product Detail:

High carbon steel shot, made out of special steel,hardened and tempered, have a content in carbon greater than 0.85%.through atomization process,spherical particles made of molten steel.Fengerda strictly controls every link of production, especially the control of deoxidation and decarbonization, temperature in quenching process, as well as the elimination of pores and abnormity after forming, which improves the product to a new level.

Key Specifications:

|

PROJECT |

SPECIFICATION |

TEST METHOD |

|||

|

CHEMICAL COMPOSITION |

|

0.8-1.2% |

P |

≤0.05% |

ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

|

Si |

≥0.4% |

Cr |

/ |

||

|

Mn |

0.35-1.2% |

Mo |

/ |

||

|

S |

≤0.05% |

Ni |

/ |

||

|

MICROTRUCTURE |

Homogeneous Martensite or Bainite |

GB/T 19816.5-2005 |

|||

|

Density |

≥7.0*10³kg/m³(7.0kg/dm³) |

GB/T 19816.4-2005 |

|||

|

EXTERNALFORM |

Air hole < 10%. Conjoins. Sharp corner. Deformity Rate< 10% |

Visual |

|||

|

HARDNESS |

HV:390-530(HRC39.8-51.1) |

GB/T 19816.3-2005 |

|||

Processing Steps:

Advantages:

High Carbon Rounded Steel Shot using the traditional manufacturing technique,used for blast cleaning and shot peening mainly.Perfectly controlled heat treatments provide it with optimum resilience and resistance to fatigue.

and finish metal parts that require increased wear and fatigue properties. In the process, shot bombards the metal part, creating small dimples in the surface.

The dimples cause compression stresses in the surface of the part, increasing the metal’s resistance to cracks, fatigue, and corrosion. Shot peening is used for critical, high-wear components such as gears, shafts and metallic skins for advanced aerodynamic products.

Applications:

Our high carbon steel shot is used in various applications like; desanding, descaling, cleaning, shot peening etc.. The centrifugal atomization process and double heat treatment at the Airblast plants, as well as continues quality control measures, ensures the shot to be of the highest quality.

Surface blast cleaning of forgings, heattreated pieces, steel pipes, sections and steel structures, surface treatment before painting, shot peening of work pieces.

Surface blast cleaning of stainless steel plates, thin steel plates, non ferrous alloys, dacromet coat.

With responsible good quality method, good status and excellent client services, the series of solutions produced by our company are exported to lots of countries and regions for Top Suppliers China High Quality Stainless Steel Blast Media Cut Wire Shot SUS304 Cw0.8, Our firm warmly welcome friends from everywhere in the globe to visit, examine and negotiate business enterprise.

Top Suppliers China Steel Shot, Stainless Steel, Our solutions are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!